Apple Mac Repair Graphics Problem

Understanding Graphics Problems and GPU Chip Failures

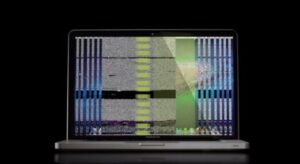

Graphics problems are quite common and typically present themselves in the following ways.

Graphics issues are a common problem in Apple Macs, and they often manifest as screen glitches, crashes, or freezing. One effective way to address these problems is by reballing the GPU chips, a process far superior to the commonly used reflow method, which we also used to rely on.

The key reason behind GPU chip failure lies in the effects of thermal cycling on lead-free solder. Over time, this leads to:

- Weak solder bonds

- Solder voids

- Organic matter buildup

- Cracking and brittle joints

- “Black pad” formation from brittle intermetallic layers

- Pad cratering, where BGA ball pads lift off the board

These issues arise because lead-free solder, required by regulations in consumer electronics, is more brittle and susceptible to damage from repeated heating and cooling cycles (thermal cycling). Simply put, the solder spheres degrade over time due to heat stress.

Why Reballing is Superior

Unlike reflowing, which merely reheats the solder, reballing involves replacing the old, damaged solder balls with new ones. We use leaded solder balls, which are far more resistant to thermal cycling than the brittle lead-free alternatives.

To further reduce heat stress and improve longevity, we have developed a custom heat sink modification that reduces GPU temperatures by up to 30%.

Limitations and Solutions

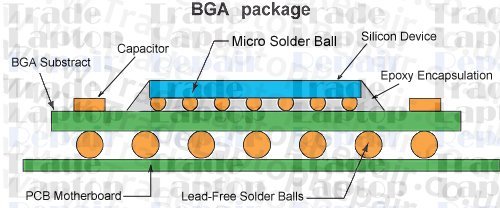

While most BGA (Ball Grid Array) ICs can be reballed, not all are suitable due to their size and thickness. Thinner, more fragile BGA packages are prone to warping, making reballing impossible. In such cases, we carefully reflow the chip using custom reflow profiles and a specialized flux developed by the patent holders of infrared rework stations. This high-quality flux leaves no harmful residue, unlike the standard yellow flux used by other repair centers.

Our Process

For most BGA ICs, we successfully reball and refit the chips, using custom profiles to ensure a perfect fit. This method works about 80% of the time without issues.

However, BGA ICs are made up of two layers of solder balls:

- Bottom Layer: These are visible and can be reballed.

- Top Layer: These are micro solder balls, encapsulated under the top silicon layer of the BGA IC package, and cannot be reballed.

While the top layer is less affected by thermal cycling, it can fail on rare occasions. If this happens, the entire BGA IC must be replaced, as no one can reball the sealed top layer.

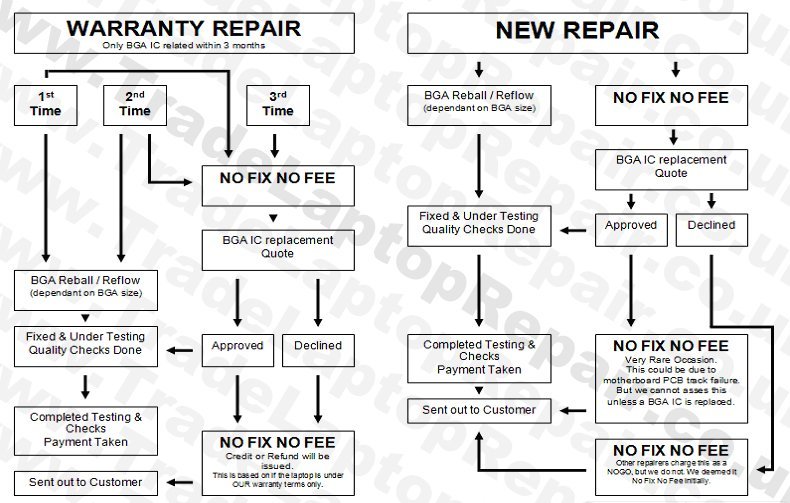

Warranty and Repair Advice

Most laptops returned under warranty are due to issues with these BGA ICs. Unfortunately, there’s no way to know if the top layer of solder balls is faulty until the laptop experiences repeat failures under warranty.

To minimize future failures, we propose replacing faulty BGA ICs when necessary. We will always attempt to repair your device using reflow or reballing under our fixed-rate motherboard repair fee. Only in cases where the BGA IC needs replacement will additional costs apply, typically between £10-20. We will advise you on costs and lead times for replacement chips on a case-by-case basis.

Our goal is to keep your repair costs as low as possible, but we may recommend replacing BGA ICs for both new repairs and warranty repairs when we suspect the chip is faulty.